|

Satish Lele lelepiping@gmail.com |

View this page as YouTube Video Presentation

Summary of HAZOP Analysis:

What is HAZOP: A Hazard and Operability (HAZOP) study is a structured and systematic examination of a planned or existing process or operation in order to identify and evaluate potential hazards and operability problems. Or to ensure the ability of equipments in accordance with the design intent.

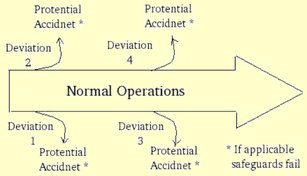

The HAZOP analysis technique uses a systematic process to identify possible deviations from normal operations and ensure that appropriate safeguards are in place to help prevent accidents. It uses special adjectives combined with process conditions to systematically consider all credible deviations from normal conditions. The adjectives, called guide words, are a unique feature of HAZOP analysis.

In addition to its utility in Quality Risk Management, HAZOP is also commonly used in risk assessments for industrial and environmental health and safety applications.

Definitions: When describing the HAZOP methodology, the following definitions1 are useful:

Hazard - Potential source of harm. Deviations from design or operational intent may constitute or produce a hazard. Hazards are the focus of HAZOP studies, and it should be noted that a single hazard could potentially lead to multiple forms of harm.

Harm - Physical injury or damage to the health of people or damage to property or the environment. Harm is the consequence of a hazard occurring and may take many forms: patient or user safety, employee safety, business risks, regulatory risks, environmental risks, etc.

Risk - Combination of probability of occurrence of harm and the severity of that harm. In a strict sense, “risk” is not always explicitly identified in HAZOP studies since the core methodology does not require identification (also referred to as rating) of the probability or severity of harm. However, risk assessment teams may choose to rate these factors in order to further quantify and prioritize risks if needed.

Usage: HAZOP is best suited for assessing hazards in facilities, equipment, and processes and is capable of assessing systems from multiple perspectives:

Design: Assessing system design capability to meet user specifications and safety standards. Identifying weaknesses in systems.

Physical and operational environments: Assessing environment to ensure system is appropriately situated, supported, serviced, contained, etc.

Operational and procedural controls: Assessing engineered controls (ex: automation), sequences of operations, procedural controls (ex: human interactions) etc. Assessing different operational modes – start-up, standby, normal operation, steady & unsteady states, normal shutdown, emergency shutdown, etc.

A systematic, highly structured assessment relying on HAZOP guide words and team brainstorming to generate a comprehensive review and ensure that appropriate safeguards against accidents are in place.

Typically performed by a multidisciplinary team.

Applicable to any system or procedure.

Used most as a system-level risk assessment technique.

Generates primarily qualitative results, although some basic quantification is possible.

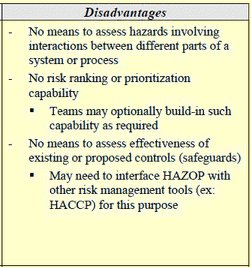

- Limitation of the HAZOP Technique:

Requires a well-defined system or activity: The HAZOP process is a rigorous analysis tool that systematically analyzes each part of a system or activity. To apply the HAZOP guide words effectively and to address the potential accidents that can result from the guide word deviations, the analysis team must have access to detailed design and operational information. The process systematically identifies specific engineered safeguards (e.g., instrumentation, alarms, and interlocks) that are defined on detailed engineering drawings.

Time consuming: The HAZOP process systematically reviews credible deviations, identifies potential accidents that can result from the deviations, investigates engineering and administrative controls to protect against the deviations, and generates recommendations for system improvements. This detailed analysis process requires a substantial commitment of time from both the analysis facilitator and other subject matter experts, such as crew members, engineering personnel, equipment vendors, etc.

Focuses on one-event causes of deviations: The HAZOP process focuses on identifying single failures that can result in accidents of interest. If the objective of the analysis is to identify all combinations of events that can lead to accidents of interest, more detailed techniques should be used.

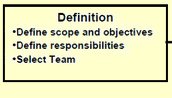

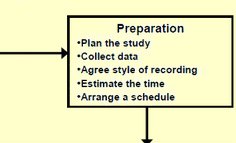

- Procedure for HAZOP Analysis:

- Definition of some useful items:

Node: Node is some specific sections of the system in which (the deviations of) the design / process intent are evaluated. A node can be a subsystem, a function group, a function or a sub function.

Deviation: A deviation is a way in which the process conditions may depart from their design / process intent. It is created by combining guide words with process parameters resulting in a possible deviation from design intent.

Process parameters: The process parameters is the relevant parameter for the conditions of the process. For example, voltage, data, direction, etc.

Guide words: The guide words, or secondary keywords, applied in conjunction with a Primary Keyword, these suggest potential deviations or problems. For example, less, more, no, reverse, etc.

- Define the system or activity: The system boundaries should be specified and clearly defined. By doing these, analysts can avoid overlooking key elements at interfaces.

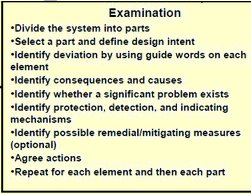

- Main process of the HAZOP Analysis:

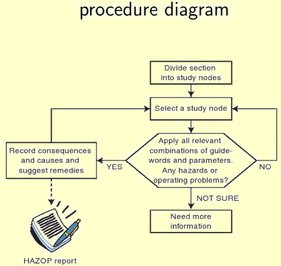

Divide the system into sections and develop credible deviations.

Determine the cause of the deviation and evaluate the consequences/problems.

Find the safeguard which help to reduce the occurrence frequency of the deviation or to mitigate its consequences.

Recommend some actions to against the deviation more effectively,

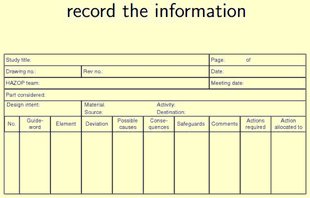

Record the information.

Repeat procedure.

First we should divided the system into several sections and choose one as a node. Of course we should know the design intent of this node so that we could find the process parameters from it. After that we should apply some guide-word to match these parameters and both of them compose a deviation.

Guide Word + System Parameter = Deviation

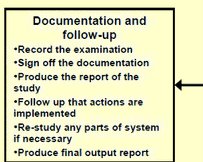

- Conduct HAZOP reviews

- Introduce the team members

- Describe the HAZOP approach

- Conduct the analysis

- Use the results in decision making

- Judge acceptability

- Identify improvement opportunities

- Make recommendations for improvements

- Justify allocation of resources for improvements

- Definition of some useful items:

- HAZOP about Stepper Motor Demo

- What is Stepper Motor Demo: Stepper Motor Demo is a RTLinux Application which controls the running status of a small stepper motor. Our intent is to analysis the Hazards and Operability of a system by analyzing a actual example on the stepper motor demo.

- Specify the problems which include some issues: As a system with the motor, it may appear some problems as following:

- The motor burn down or cannot rotate forever

- The motor rotate too quick

- The motor do contrarily what you want it do, for the direction is reverse

- Divide the system by interfaces

- Develop the deviations

- Analysis the interface 3

to get all the information as a eBook

to get all the information as a eBook